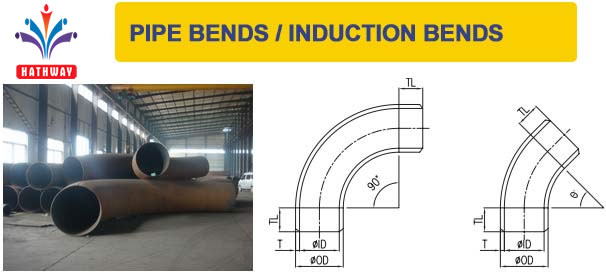

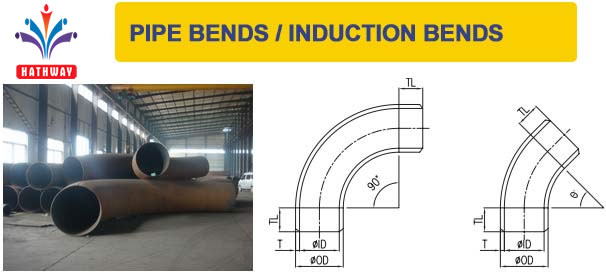

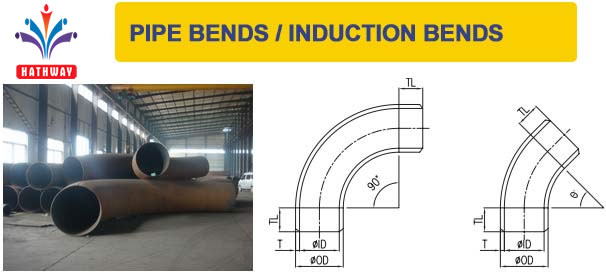

PIPE BENDS / INDUCTION BENDS

Pipe bends, piggable bends, u-bends, return bends, Hot Induction Bends, miter bends manufacturer, exporter & suppliers in India. Yes we sell ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43 carbon, alloy, stainless steel Bends – 3D, 4D, 5D, 6D, 8D, 10D- Pipe Fittings

Manufacturers, dealer, distributor, stockist & suppliers of Pipe bends/ Hot Induction Bends

ASME/ANSI B16.9 Pipe bends/ Hot Induction Bends manufacturer

- ASME/ANSI B16.9 Pipe bends/ Hot Induction Bends Dimensions

- ASME/ANSI B16.9 Pipe bends/ Hot Induction Bends Tolerances

- ASME/ANSI B16.9 Pipe bends/ Hot Induction Bends Chemical Analysis

- ASME/ANSI B16.9 Pipe bends/ Hot Induction Bends Tensile Requirements

- ASME/ANSI B16.9 Pipe bends/ Hot Induction Bends Testing

- ASME/ANSI B16.9 Pipe bends/ Hot Induction Bends Pressure Ratings

- Dimensions, Wall Thickness and Weights of ANSI/ ASME Buttweld Fittings to ASTM A403 / A815 ASME B16.9

- Dimensions, Wall Thickness and Weights of Buttweld Fittings to ASME B16.9, ASME B16.28 and MSS SP75

- Factory-Made Wrought ASME/ANSI B16.9 Pipe bends/ Hot Induction Bends

- ASME/ANSI B16.9 Pipe bends/ Hot Induction Bends Price in India » Please visit our Shop to buy Pipe Fittings Online, price available material/ size wise in our shop

Pipe bends/ Hot Induction Bends manufacturing in Our Work Shop

Hathway / Dynamic is an approved manufacturer of Pipe bends/ Hot Induction Bends to requirements of BVIS, IBR, BARC, DNV, BHEL & we are ISO 9001:2008, 14001:2004, OHSAS 18001:2007 certified company.

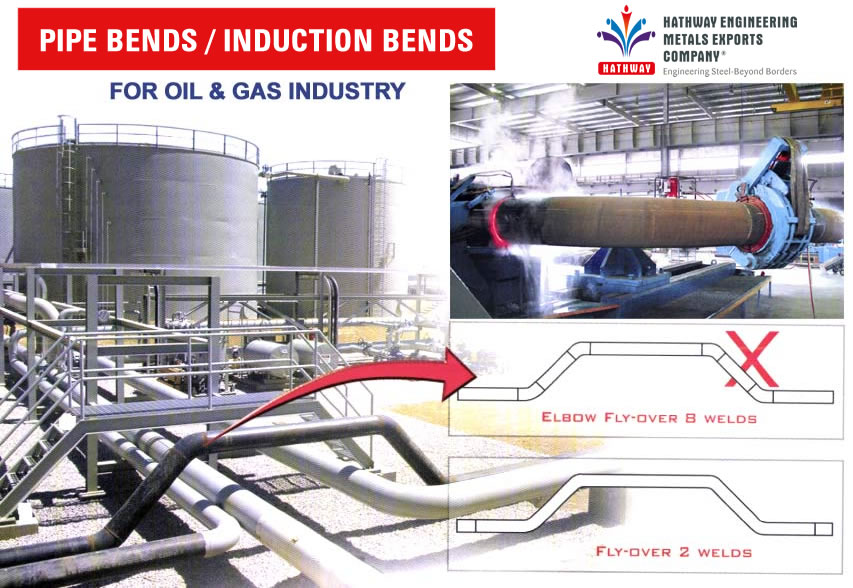

Induction Bending is a controlled high precision bending of pipes and shapes under localized heating using high frequency induction electric power. This method is useful to bend pipes in specific radius, it is a flexible and versatile method to solve or simplify many difficult situations for mechanical and construction contractors in oil, gas, petrochemical plants and architectural structures to substitute for elbows and fittings and to make new shapes as per customer’s specification.

Pipe bends/ Hot Induction For Oil & Gas Industry

Type of Butt weld Pipe end caps/ Plugs :

- Seamless Butt Welding Fittings/ Pipe end caps/ Plugs to ASTM A403WP-S 304/304L or 316/316L, UNS S31803 fittings, ANSI B16.9, annealed and quenched, bevelled ends to ANSI B16.25, hardness to NACE MR0175-latest edition, IC to ASTM A262E and PMI tested, certificate to EN 10204/3.1B.

- Welded Butt Welding Fittings/ Pipe end caps/ Plugs to ASTM A403WP-W304/304L or 316/316L, ANSI B16.9 cold formed, annealed and quenched, bevelled ends to ANSI B16.25, hardness to NACE MR0175-latest edition, IC to ASTM A262E and PMI tested, certificate to EN 10204/3.1B

- All seamless fittings are from ISO and PED approved mills

Do you need your Pipe end caps/ Plugs shipped to you internationally? Not only do we ship all of our fittings & flanges globally, we will consolidate the order for you and ship it to the closest port near you. We have gained several Orders of Pipe end caps/ Plugs from countries like US, Canada, Chile, Brazil, UK, Italy, Belgium, France, Portugal, South Africa, Nigeria, United Arab Emirates (UAE), Bahrain, Saudi Arabia, Qatar, Kuwait, Jordan, Malaysia, Thailand, Singapore, Indonesia, Sudan, Kazakhstan, Australia, Israel, Kenya, Russia, Tunisia, Vietnam, Colombia, Sri Lanka, etc.

- Pipe fitting surplus stock at Dynamic Forge & Fittings

- Pipe Fittings

- Butt Weld Fittings

- Forged Fittings

- Socket Weld Fittings

- Threaded Fittings

- Flange

Eccentric/ Concentric Pipe Reducers, Stainless Steel Reducers, Carbon Steel Reducers and alloy steel Reducers

Stainless Steel Eccentric/ Concentric Pipe Reducers

Carbon Steel Eccentric/ Concentric Pipe Reducers

Alloy Steel Eccentric/ Concentric Pipe Reducers

Eccentric/ Concentric Pipe Reducers & Pipe Fittings trade exhibition in Dubai- UAE

Pipe bends/ Hot Induction Bends Production Range

Stainless steel pipe bends, carbon steel pipe bends and special grade pipe bends are widely supplied by us to many industries such as power generation, petrochemical, shipbuilding, paper manufacturing, chemical, pharmaceutical, and fabrication. Ppe cap also known as plugs.

Buttweld Pipe Bends Production Range –Piggable Bends, Hot Induction Bends

Outside Diameter: Seamless Pipe Bends (1/2? – 24?), ERW / Welded / Fabricated Pipe Bends (2? – 36?)

Wall Thickness: 3mm – 40mm / SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Bending Radius: R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Product Angle: 0° – 180°

Value Added Services: Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering

Production Grades: Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Copper, Cupro Nickel, Inconel, Monel, Hastelloy

Manufacturing Standards

ASME: ANSI B16.9, ANSI B16.28, MSS-SP-43

DIN: DIN2605, DIN2615, DIN2616, DIN2617, DIN28011

EN: EN10253-1, EN10253-2

ASTM A403 – ASME SA403 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

ASME B16.9 – Factory-Made Wrought Fittings Buttwelding

ASME B16.25 – Buttwelding Ends ASME B16.28 – Wrought Steel Short Radius Elbows and Buttwelding Returns

MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

Stainless Steel Pipe bends/ Hot Induction Bends :

ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel Pipe bends/ Hot Induction Bends :

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Alloy Steel Pipe bends/ Hot Induction Bends :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Nickel Alloy Pipe bends/ Hot Induction Bends :

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Duplex & Super Duplex Pipe bends/ Hot Induction Bends :

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462

Pipe end caps/ Plugs Test Certificates:

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report as per client specification.

Hathway Metals offer its Products with Third Party Inspection also. The Inspection Agency can be nominated by clients or Dynamic Forge & Fittings can be arrange the TPI by World reputed Agencies like Bureau Veritas, DNV, LLOYDS, ICB and many other. Pipe bends/ Hot Induction Bends are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards

Packaging & shipping:

Pipe bends/ Hot Induction Bends Packing

Hathway / Dynamic emphasis on the packaging to ensure that there is no damage during transit the Pipe bends/ Hot Induction Bends are packed in wooden corrugated boxes foiled in bubble wraps & are marked with Grade, Lot No, Size, Degree and Dynamic Forge & Fittings Brand Mark. You can also contact us for customized marking.

Hathway / Dynamic domestic network:

Mumbai, Ahmedabad, Chennai, Delhi, Bangalore

We also have our sales representative in Hyderabad, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi, Rajkot, Tamil Nadu, Maharashtra, Jaipur, Jabalpur, Vishakapatnam, Sholapur, Davangere, New Delhi, Kakinada, Belagavi, Udaipur, Guwahati, Ludhiana

Pipe bends/ Hot Induction Bends Dimensions:

Pipe bends/ Hot Induction Bends XS (Sch80):

Pipe bends/ Hot Induction Bends XS (Sch80):